Electromagnetic Stirrers Coil

EMS ElectroMagnectic Stirrer

Principle & Benefits of EMS

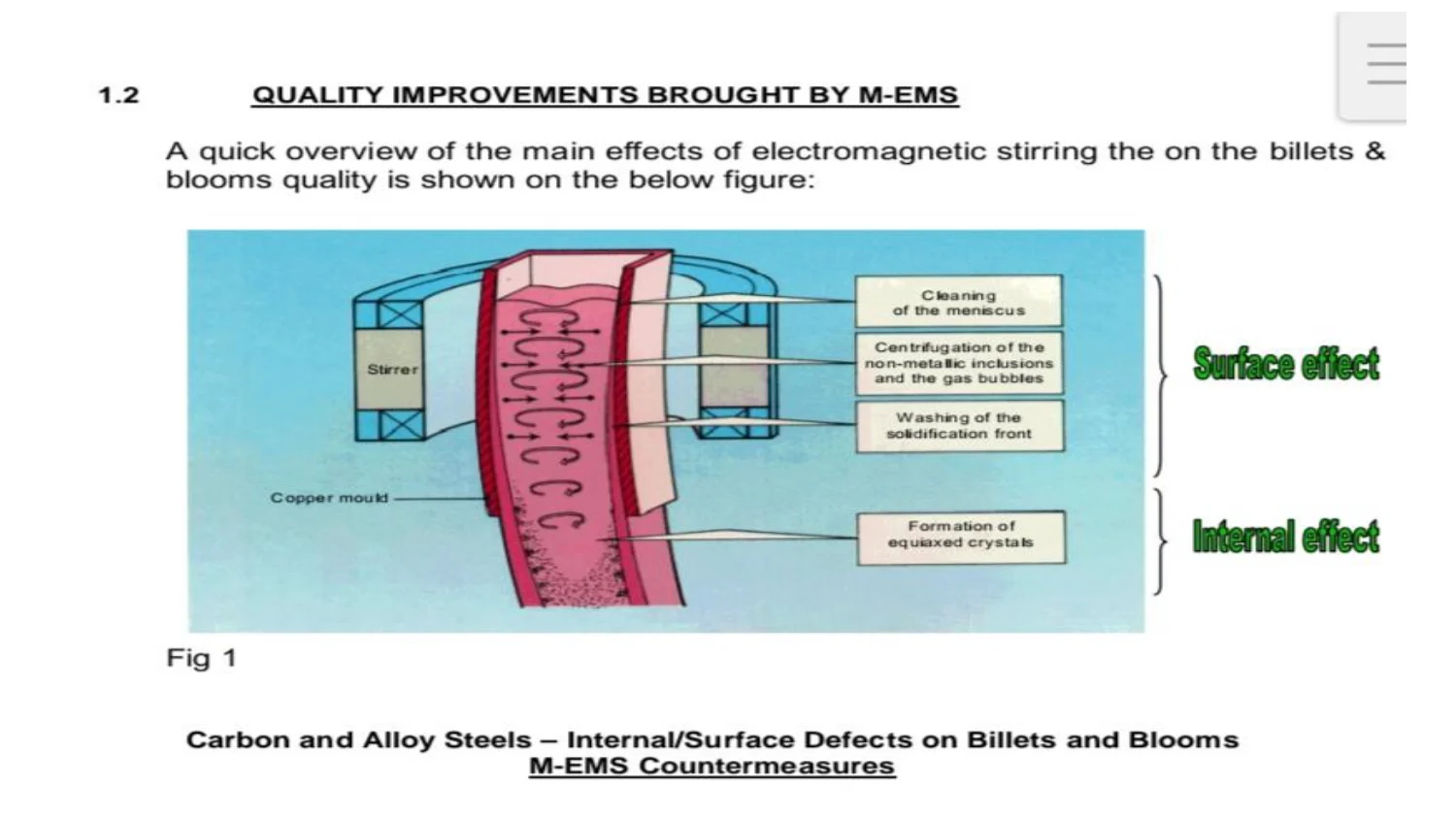

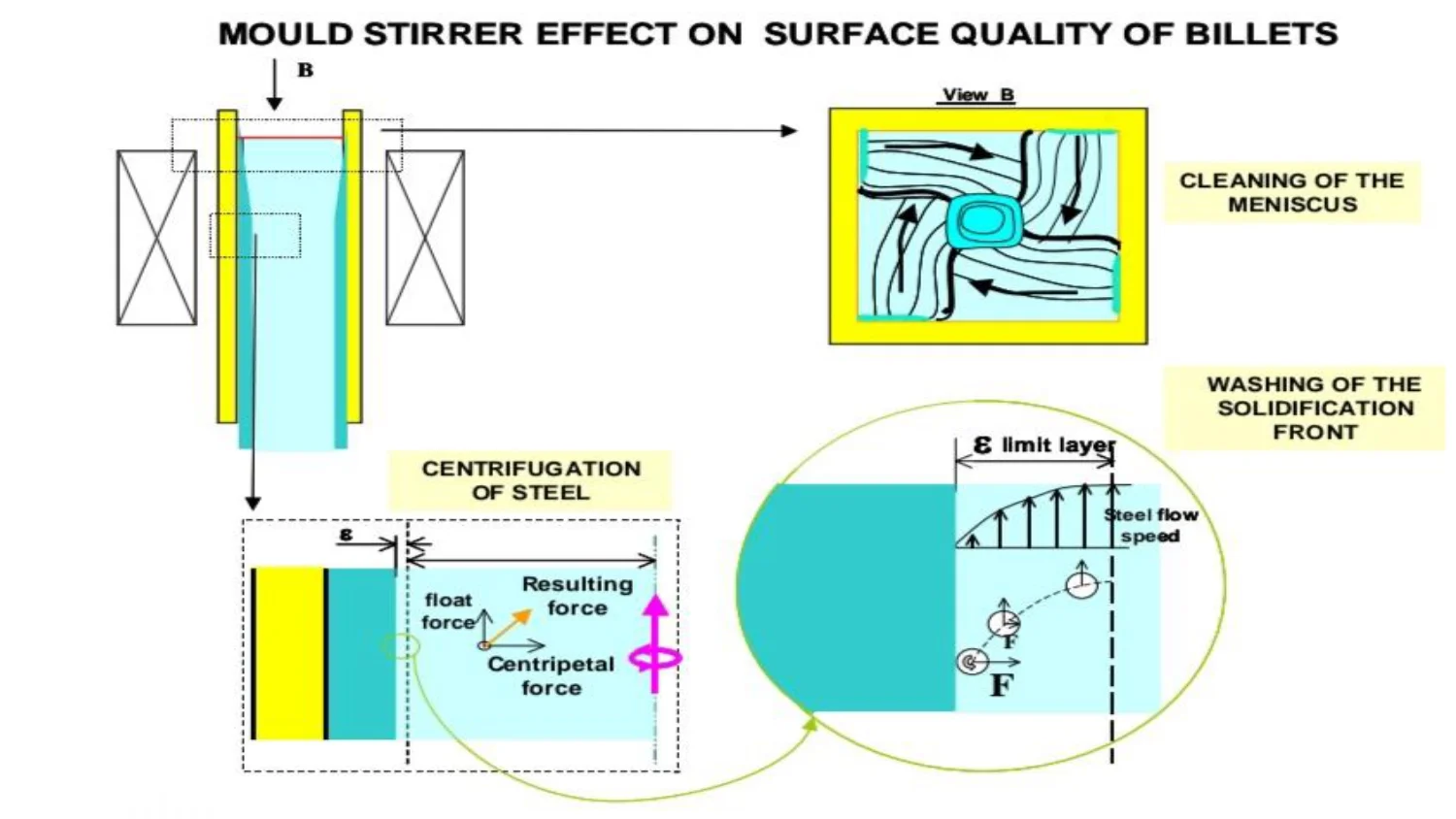

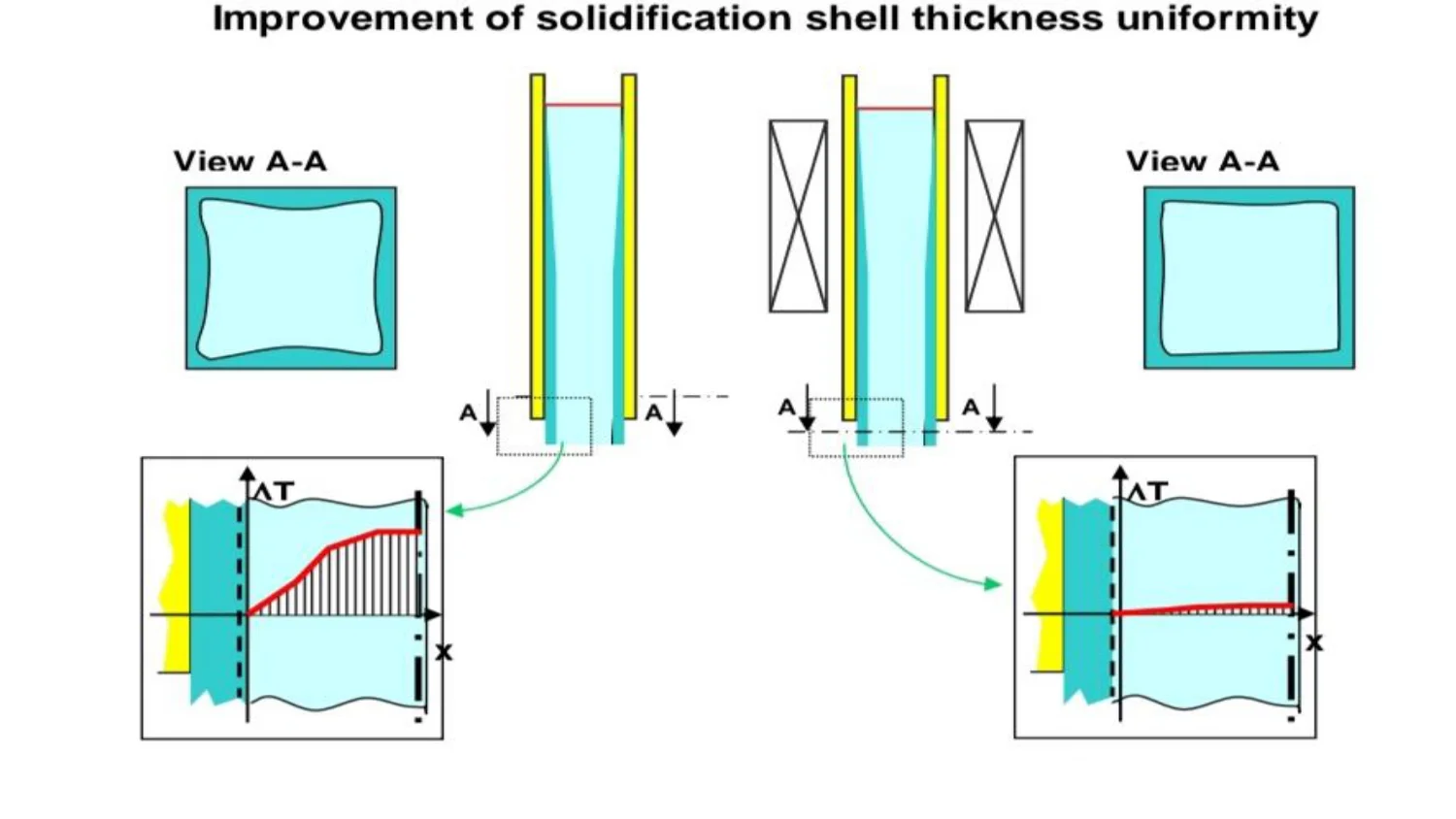

The principle of the mould electromagnetic stirrer (M-EMS) is similar to that of a three-phase asynchronous motor.

The rotation of the liquid steel is obtained by the asynchronous drive of the metal under the influence of a rotating magnetic field that is applied in a plane perpendicular to the axis of the product.

The magnetic field is generated by a cylindrical inductor installed around the mould assembly.

Our offerings

- We offer coils for sections ranging from 80x80 to 250x250 even more as per customer requirements

- Rounds can also be casted in same coils.

- We set all parameters (Current & Frequency) as per grades & sections size provided by the Customers.

- We have our own technology to develop a simple circuit to run coil through our panel which will be fully automatic.

- Customisable as per requirement.

- Necessary auxiliary support devices will be provided for in house coil testing

- Also we provide training and all material to insulate coil in house at customer site so that more life of coil can be drawn.(This feature no one provides).

- This were some of snaps for billet pattern.

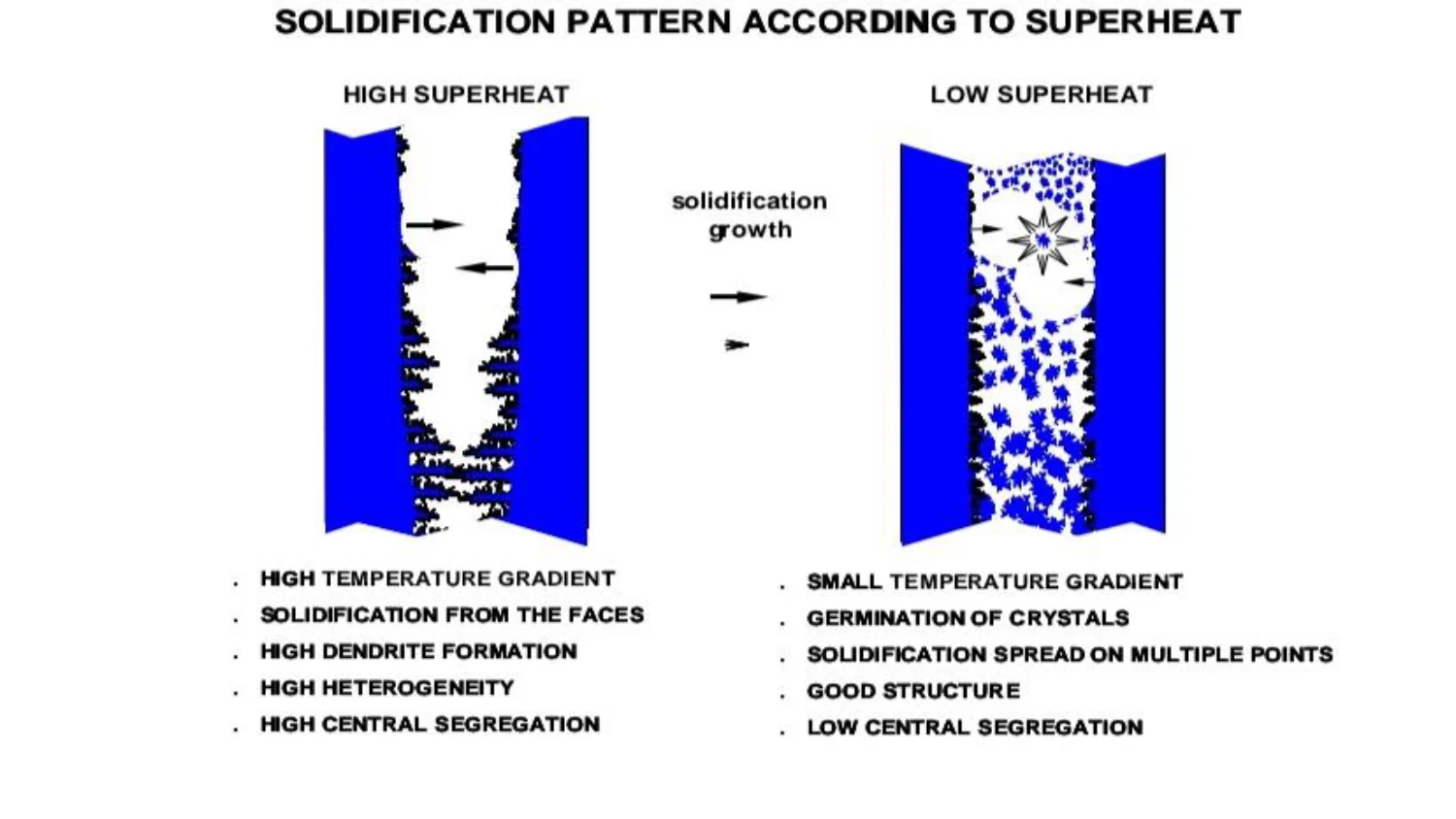

- We will provide full guarantee to generate good equiaxed zone as well as customer can compare quality of billet with EMS & without EMS.

- Also more improvement can also be done further by using AMLC.

- We provide same for further quality improvement.